Geocomposite Metal Stamping Supplier: Experience, Precision, and Flexibility

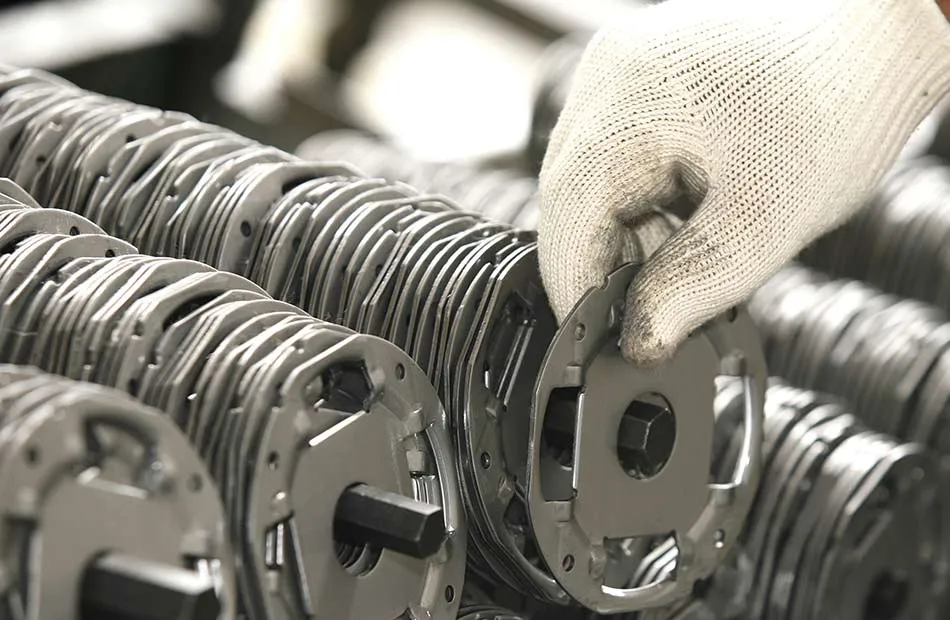

Metal stamping is a versatile metal forming technique that encompasses various processes such as punching, piercing, blanking, bending, welding, plating, and heat treating. When searching for a metal stamping supplier, it is crucial to consider certain factors to establish a productive and beneficial partnership. Working with the right supplier can result in faster production times, cost savings, and improved product quality. Conversely, an unreliable supplier can lead to delays, recalls, and unsatisfactory inspection results, negatively impacting your bottom line.

In this article, we will discuss the essential characteristics to look for in a geocomposite metal stamping supplier to ensure the best possible partnership for your organization.

Key Considerations When Selecting a Geocomposite Metal Stamping Supplier

When choosing a geocomposite metal stamping supplier, several important considerations come into play. The primary factors revolve around the supplier’s quality and capabilities.

Quality

Evaluating the quality of a geocomposite metal stamping supplier involves paying close attention to the following:

— Design: A reliable metal stamping supplier should offer design recommendations that help prevent defects and future expenses. At GeoFanTex, we excel in this aspect by designing parts based on the step-by-step metal stamping process they require. Understanding how each step affects the workpiece enables us to minimize or eliminate design costs effectively.

— Materials: The best geocomposite metal stamping suppliers work with a wide range of materials and possess in-depth knowledge of which materials are most suitable for your project. They understand the unique properties of each material and how it behaves during specific stamping processes. GeoFanTex’s expertise extends to steel, stainless steel, brass, copper, aluminum, titanium, and more. To facilitate material selection, we have developed a Material Selector Tool that provides information on bend rating, tensile strength, density, and other traits for each metal.

— Experience: A reputable geocomposite metal stamping supplier should have the necessary expertise, precision, and quality standards to manufacture your products. GeoFanTex is fully equipped to handle projects of all sizes, ranging from thousands to hundreds of millions of parts. We specialize in providing metal stamping services to industries that demand extreme precision, including the automotive, medical, and aerospace sectors.

Production Capabilities and Capacity

To ensure that your geocomposite metal stamping needs are met, it is essential to consider the supplier’s production capabilities and capacity, especially in relation to the changing demands of your industry.

— Vertically Integrated: GeoFanTex follows a vertically integrated approach, managing your project from design to delivery. We collaborate with your team and provide support from design and engineering experts, including guidance on materials, production processes, and operation sequences. Our in-house tool manufacturing capabilities are complemented by assembly and other secondary and finishing services.

— Flexibility: Recent challenges in the supply chain have led to extended lead times and increased metal prices. A flexible geocomposite metal stamping supplier can deliver consistent products and services despite market fluctuations. With 30 years of established relationships with metal vendors, GeoFanTex closely monitors market trends. Leveraging this insight, we can suggest design and material alternatives to ensure your project is completed on time, within budget, and in line with your application’s requirements.

— Response Times: Time is of the essence in business. A geocomposite metal stamping supplier should prioritize quick response times, from initial consultations to the final product. Effective and frequent communication ensures timely project completion. At GeoFanTex, we maintain open lines of communication with our clients to meet production deadlines efficiently.

— Industry Experience: It is crucial for a geocomposite metal stamping supplier to have extensive experience in creating products for your specific industry. This ensures their familiarity with industry-specific regulations and any quality standards your parts must meet. With over three decades of experience serving industries such as aerospace, automotive, medical, defense, lighting, renewable energy, and mechanical, electrical, and plumbing (MEP), GeoFanTex possesses comprehensive industry knowledge. Our engineering staff alone boasts nearly 300 years of combined experience in their respective fields.

Creating a Strong Partnership

Selecting the right geocomposite metal stamping supplier is vital for the success of your organization. By considering the factors discussed in this article, such as quality, production capabilities, flexibility, response times, and industry experience, you can establish a fruitful and enduring partnership. GeoFanTex has a proven track record in providing exceptional geocomposite metal stamping services, and our expertise and commitment make us an ideal partner for your organization’s metal stamping needs.