The Role of Geogrid Material in Industrial Air Compressors

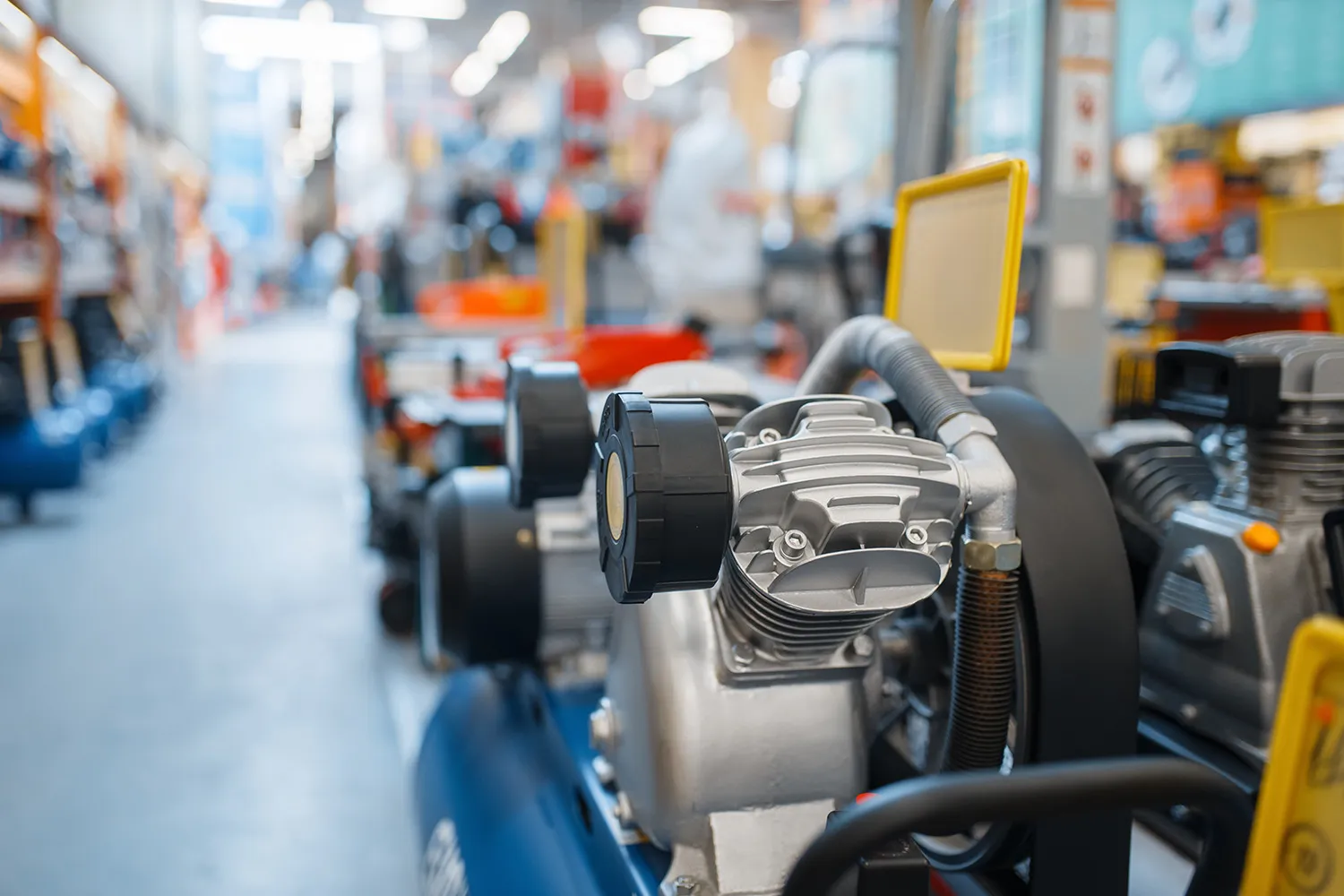

An industrial air compressor, a pivotal tool in mechanical engineering, operates as a vital device to generate pressure within compressible fluids or gases, primarily utilizing air. These compressors serve a myriad of functions across industries:

- Providing instruments or shop air

- Empowering diverse air tools, abrasive blast equipment, and paint sprayers

- Facilitating the smooth transition of refrigeration and air conditioning mediums

- Propelling gases through intricate pipelines

Compressors, akin to pumps, are classified into positive-displacement or centrifugal mechanisms. Predominantly operating within the positive displacement category, compressors differ from pumps, which tend to be predominantly centrifugal.

These industrial compressors exhibit versatility, ranging from compact glove box units ideal for tire inflation to colossal turbo compressors integral in optimizing pipeline operations.

Power Generation through Air Compression

The process of air compression involves elevating pressure beyond atmospheric levels, necessitating an input of energy. As compressed air strives to return to equilibrium, it releases stored energy while expanding back to atmospheric pressure. This unique process allows air compressors to achieve remarkably high pressures, effectively harnessing potential energy. Compressed air stands out by avoiding the need for energy conversion at the application point, showcasing an exceptional power-to-volume or power-to-weight ratio inherent in pneumatic or compressed air devices.

While it might not match the speed of electricity or the deliberateness of hydraulics, compressed air finds extensive applications. It often emerges as the preferred choice, especially in scenarios prioritizing cost-effectiveness and efficiency.

The paramount advantage of compressed air lies in the enhanced control it offers, devoid of the hazards associated with electrical shock or the fire risks linked to oils. Nonetheless, strict adherence to safety codes and regulations governing compressed air handling remains crucial.

Active Air and Energy Air Integration with Geogrid Material

Active air represents compressed air directly interacting with products, crucial in preserving food, beverages, electronics, pharmaceuticals, and chemical industries. In contrast, energy air characterizes compressed air primarily used for transmitting and storing energy, powering pneumatic tools, and driving mechanical work.

Given the divergence in applications, ensuring superior active air quality becomes paramount, especially when compared to energy air. Hence, effective filtration plays a pivotal role in eliminating contaminants such as dust, water, or oil. Notably, the integration of diverse geogrid materials into compressor structures significantly enhances stability and structural integrity, ensuring robustness in various industrial settings.

Understanding the intricate interplay between industrial air compressors and a diverse range of geogrid materials highlights their crucial role in ensuring structural reliability and operational efficiency across multifaceted industrial applications.