Progressive Die Stamping Process: Enhancing Efficiency and Quality with Geotextile

Progressive die stamping is a high-speed process that transforms metal strips into durable parts used across various industries. By incorporating geotextile into the process, manufacturers can achieve cost savings and enhance the quality of the fabricated parts.

Overview of Progressive Die Stamping Process with Geotextile

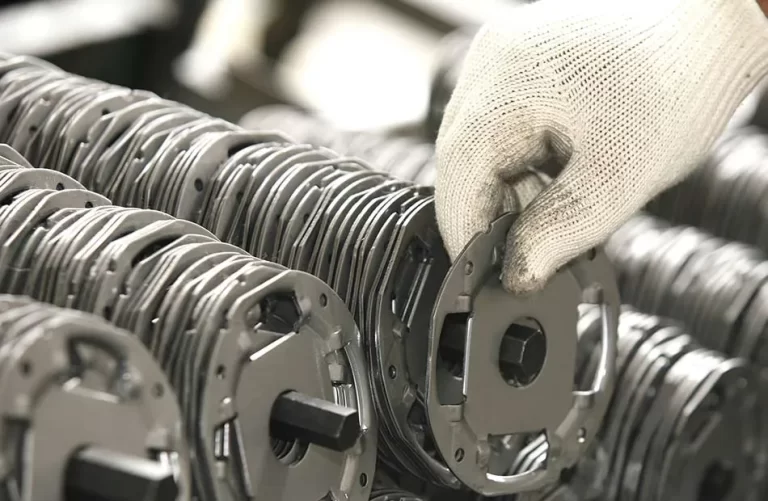

The progressive die-stamping process consists of several stages:

- Proper Positioning of Progressive Die: The progressive die is accurately positioned within the stamping press to ensure smooth opening and closing movements as the press is raised or pressed down.

- Metal Strip Execution: Metal strips are fed through the stamping die, where each press stroke precisely performs blanking and forming actions. Geotextile, a versatile and cost-effective material, can be effectively utilized in this stage to shape and fabricate parts.

- Progressive Processing: The metal strip is automatically advanced to the next station, where different processes are carried out progressively to achieve the desired design. Geotextile can contribute to improved efficiency and cost savings at this stage.

- Final Part Cutting and Further Processing: At the last station, the finished part is cut free from the feed line, and ready for additional processing or assembly. Geotextile can ensure the dimensional stability and durability of the final part.

Optimizing Stock Strip Layout and Design with Geotextile

Manufacturers employ advanced computational models to design the progressive die, strategically placing punches, bends, and holes on the blank strip. Geotextile can be integrated into the stock strip layout and design, offering flexibility, strength, and cost advantages.

Utilizing Geotextile in Tool Steel and Die Set Machining

Once the stock strip design is finalized, CNC machining processes are employed to create precise die blocks. Geotextile can be leveraged in this stage to enhance part repeatability and ensure high-quality standards. Thorough quality control measures are implemented to validate the precision of the dies before initiating production.

Secondary Processing: Grinding, Heat Treating, and Geotextile

To further strengthen the parts, heat treatments are applied, surpassing the critical transformation temperature of the alloy. Rapid cooling during the heat treatment process enhances the durability and dimensional stability of the parts. Additionally, grinding may be employed for parts requiring exceptional dimensional accuracy and surface quality. Geotextile can be compatible with secondary processing techniques, contributing to enhanced part performance.

Geotextile-Enabled Progressive Die Stamping: Efficiency and Quality Combined

By incorporating geotextile into progressive die-stamping processes, manufacturers can achieve significant benefits in terms of cost efficiency and part quality. Geotextile’s versatility, strength, and cost-effectiveness make it a game-changer in the metal stamping industry.