Cost Savings and Efficiency with Geosynthetic Materials

Metal stamping costs can vary significantly with minor changes in the properties of the raw materials you use. For instance, harder materials take more effort and time to stamp, making them more expensive. But, you can save time and money by using a softer or less abrasive material that does not compromise the required quality standards of your part. Some materials have huge price differences, yet they can deliver similar properties.

Geosynthetic materials, a type of synthetic material engineered for various applications, offer an excellent alternative for metal stamping. By incorporating geosynthetic materials into your manufacturing process, you can achieve significant cost savings while maintaining the quality and structural requirements of your parts.

Switching to geosynthetic materials can be a prudent choice, especially when considering the current component requirements and the price of materials in the market. If you were using a certain material for the original component design due to its particular characteristics, but the minimum standards for the part have changed, you can safely switch to cost-effective geosynthetic materials without compromising performance.

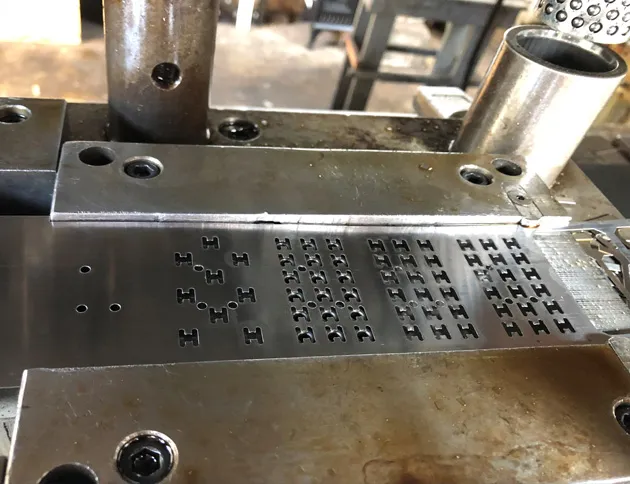

In addition to material considerations, evaluating the tooling requirements is crucial when working with a metal stamping company. A minor change in tooling can have a substantial impact on costs and production time. By reviewing your tooling requirements and exploring the possibilities of using geosynthetic materials, you can reduce complexity while maintaining functionality, leading to cost savings and improved efficiency.

Geosynthetic materials offer advantages in terms of tooling requirements as well. With their unique properties, they can simplify component designs, minimize repair and re-tooling frequency, and reduce production downtime. By incorporating geosynthetic materials into your metal stamping process, you can avoid unnecessary changes in tooling requirements and mitigate issues such as excessive abrasive wear and fatigue cracking.

Moreover, production volume plays a significant role in determining costs and timelines. When there is increased demand for your components, it becomes essential to streamline product designs for improved manufacturability and production efficiency. Geosynthetic materials, with their versatility and cost-effectiveness, can be instrumental in achieving these objectives.

By leveraging the benefits of geosynthetic materials, you can optimize raw materials and finishing costs based on the volume purchased. Placing blanket orders for your parts over a given time period with smaller releases can lead to cost savings. Additionally, revising complex features and optimizing your components’ design can enhance quality control and increase the intervals between scheduled maintenance on your tooling.

Understanding the Estimated Annual Usage (EAU) of your parts is crucial for making informed decisions. Based on the volume and frequency of your production runs, you can explore different options for tool material and coatings, including multiple cavity tooling, that can help save money while achieving the desired results. Adjusting the material from your original design, such as reducing thickness or switching to a more malleable metal, can extend the die life and further reduce material costs.

When unexpected increases in volume occur, effective communication with your metal stamping provider is essential. Sharing the product volume upfront helps determine whether additional tools or dies are necessary to accommodate the higher output.

In conclusion, by integrating geosynthetic materials into your metal stamping process, you can optimize costs, improve efficiency, and maintain the required quality standards of your parts. With careful evaluation of material options, tooling requirements, and production volume, you can achieve substantial benefits in terms of cost savings, streamlined production, and enhanced performance. Embrace the potential of geosynthetic materials and revolutionize your metal stamping operations.